OEM&ODM Service

• According to your design we can be your workshop.Take advantage of close cooperation with moulding factory ,skilled worker and advaced equipment and own test lab,we can offer.

• Specific designs and material combinations.

• Solutions adapted to current and future isolation technologies for aseptic filling.

• Cross-functional flexible Project Management.

• Solutions that comply with the latest regulatory requirements.

One Stop Trading Service

• As friend company of many other pharmaceutical packaging companies, we are good business partner with pharmaceutical glass vials,flip off caps,and pefilled syringe companies in China.

Lab Service

• Analysis for the characterization of extractables , leachables and other chemical properties.

• Extractable and toxicology characterization packages ready for submission to the other regulatory bodies.

• Tomography used as a non-destructive tool to evaluate packaging systems, drug delivery devices and final drug products.

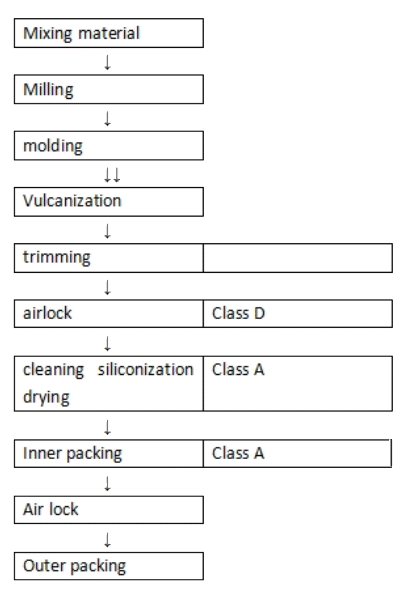

Flow Chart

Laboratory Photos